Why Custom Automation Beats Off-the-Shelf Solutions in High-Stakes Manufacturing

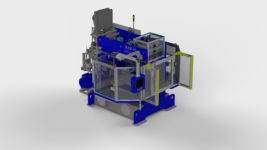

When the stakes are high — and let’s be honest, in manufacturing, they almost always are — the machinery you rely on has to work for you, not the other way around. And that’s exactly where the debate between custom vs off the shelf automation comes roaring in. Sure, an … Why Custom Automation Beats Off-the-Shelf Solutions in High-Stakes Manufacturing